We always use the most suitable modernizing machines and equipment to produce high quality products at reasonable prices. You can rely upon us, especially when you require premium printing with strictly quality control process

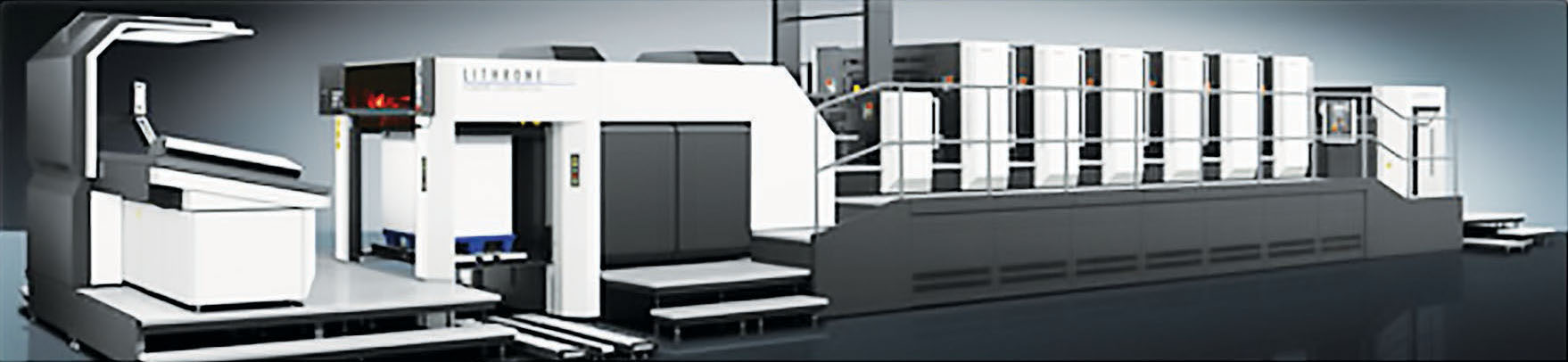

5-COLOR OFFSET PRINTER

The most modernizing generation of Komori – Japan – manufactured in 2016

Due to short set-up time and color stability during running time, offset printer of Japanese Komori’s latest generation is used to make high standard printing products of Disney and Crayola.

1/1 OFFSET PRINTER

Stable industrial generation of Mitsubishi, specializing in printing book for export

Installed in 2016, 1/1 offset printer can print on both sides. It is used to run 1-color high quality pages of books and catalogues. With our experience, we know how to operate this machine in the best condition.

4-COLOR OFFSET PRINTER

Heavy industrial generation of Mitsubishi, installed in 2008

Diamond printer has been operated smothly during the past years. With the ability to connect to CIP4 and to run stably, it took the main role to create our quality standard in the international market. Now this machine is used to print packing components which require stable quality and fast delivery. Its productivity is better comparing to others…

PRE-PRESS AND CTP SYSTEM

The most modernizing process which gives CTP plates compying with international standards

Platerite CTP machine of Japanese Dainippon Screen and the latest pre-press process help us to standardize all files to PDF-X format as Fogra standard before developing plates. Anh Khoa’s Bother is the first company in Vietnam who can make proof in accordance with offset mass printing sheets. All files, plates and proofs meet ISO 12657/2/7 standard before handling to mass production.

2-COLOR OFFSET PRINTER

Stable industrial generation of Mitsubishi & Komori, installed in 2016

Two 2-color offset printers are used to make pantone-color and gloss/matte coated print. We also take one of them for training purpose. The machines are well-maintained and running in very good conditions.

POST-PRESS SYSTEM

Optimized for every kind of product, new investment considered when developing new products

We make sure that all post-press processes are taken in house and met our strictly internal standards. All machines and equipment are suitable for every kind of products like: standard books, hardcover books, spring books, premium boxes, pakaging stuff, catalogues, magazines, labels and ect.

PACKING SYSTEM

We specialize in packing with all packaging stuff made by ourselves

As a packaging expert, besides printed products used in packing process, we also supply plastic blister and box to keep markers, paint bottles, clay as well as other toys for children. We are equipped with a lot of machines to make shrink wrap, date code, barcode,… Our logistic system is professional enough to pack complex products with many components.

In 2016, we packed more than 10 million products from premium toy gift sets to multi-material marker boxes.

QUALITY CONTROL SYSTEM

All of our printing and finishing process is controlled by specialized equipment

To get right numbers and data of printing process for QA/QC, we use Offset process control equipment Itellitrax – the latest generation of X-Rite produced in late 2016. This help our printers to understand exactly the status of printing sheet instead of getting personal feeling. Then they can take right and suitable monitoring actions. After finishing print job, the equipment will generate a quality report used as the guideline for QA/QC’s decision.

We also invested in inspection machine of Imavision in 2017. It has 2 highest resolution Cameras (4K) to scan printing sheets. It then automatically compares the scanned image with standard image set in advance. All sheets which are different from the standard one in color, lines, demension,.. will be rejected. Reports issued by the machines after checking will help our QA/QC and customers to believe much more in the quality of printing products.